AGVs

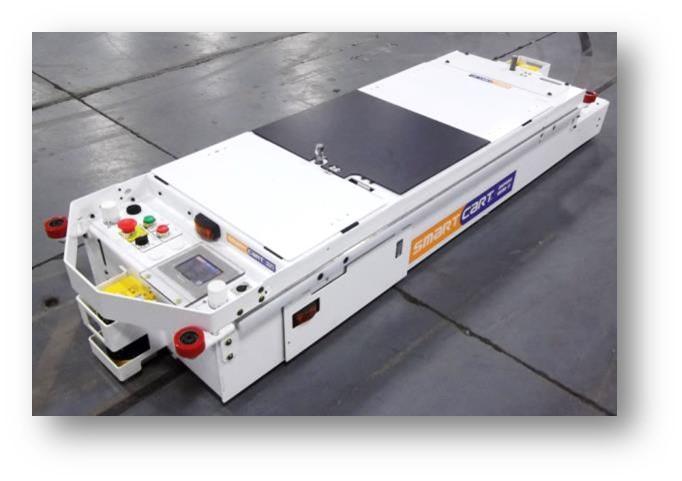

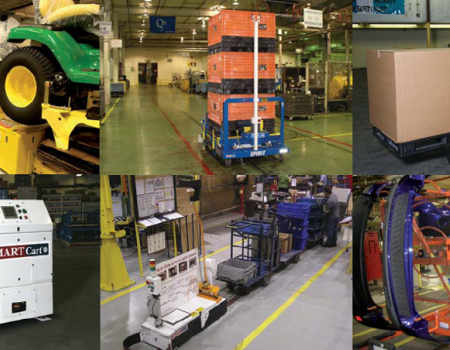

DR Storage Systems is a supplier of Automatic Guided Vehicles (AGVs).

Automated Guided Vehicles (AGVs) are mobile robotic systems used for material handling and transportation in various industries. These vehicles are equipped with sensors, navigation systems, and control software that allow them to move autonomously and efficiently within a facility. Here are some benefits of using automated guided vehicles:

- Labor Efficiency: AGVs reduce the need for manual labor in material handling tasks, leading to labor cost savings and allowing workers to focus on more value-added activities.

- 24/7 Operation: AGVs can operate around the clock without the need for breaks, contributing to continuous and uninterrupted material movement.

- Consistent Performance: AGVs follow programmed paths and tasks precisely, ensuring consistent and reliable execution of material handling processes.

- Improved Safety: AGVs are equipped with sensors and safety features that enable them to navigate around obstacles, avoid collisions, and operate safely in shared spaces with humans.

- Reduced Human Errors: The automation provided by AGVs minimizes human errors, such as incorrect product placement, mishandling, and data entry mistakes.

- Optimized Workflow: AGVs can be programmed to follow optimized paths, minimizing travel distances and optimizing the layout of the facility for improved efficiency.

- Flexibility in Routing: AGVs can adapt to changes in the production floor layout by adjusting their routes and tasks through reprogramming, minimizing disruptions during facility changes.

- Scalability: As operations grow, additional AGVs can be added to the fleet to accommodate increased material handling demands without major infrastructure changes.

- Customizable Tasks: AGVs can be configured to perform various tasks, such as material transport, loading and unloading, sorting, and more, based on the needs of the facility.

- Data Collection and Analysis: Many AGVs are equipped with sensors that collect data on material movement, allowing for performance analysis and process optimization.

- Integration with Systems: AGVs can integrate with other automation systems, such as conveyor systems, robotic arms, and warehouse management software, creating a comprehensive and efficient material handling ecosystem.

- Real-Time Tracking: AGVs can provide real-time tracking and visibility into the movement of goods, enhancing inventory management and process control.

- Reduction in Product Damage: AGVs handle products with care and precision, reducing the risk of product damage compared to manual handling.

- Enhanced Space Utilization: AGVs can maneuver in tight spaces and utilize vertical storage solutions, maximizing the efficient use of available storage and operational areas.

- Reduced Congestion: AGVs can operate in areas with limited space without causing congestion, allowing for smoother material flow in busy environments.

- Adaptable to Various Industries: AGVs are used in industries such as manufacturing, warehouses, distribution centers, healthcare, and automotive, showcasing their versatility.

Automated Guided Vehicles offer a multitude of advantages that improve efficiency, safety, and overall productivity in material handling operations. Their ability to work collaboratively with other automation technologies and adapt to changing needs makes them an essential component of modern facilities seeking to optimize their logistics and production processes.

Our project managers provide seamless integration between each manufacturer involved and the owner, while our certified installation & repair technicians bring over 25 years of experience.

Request a quote today to connect with our team.

About Us