Turntables & Carousels

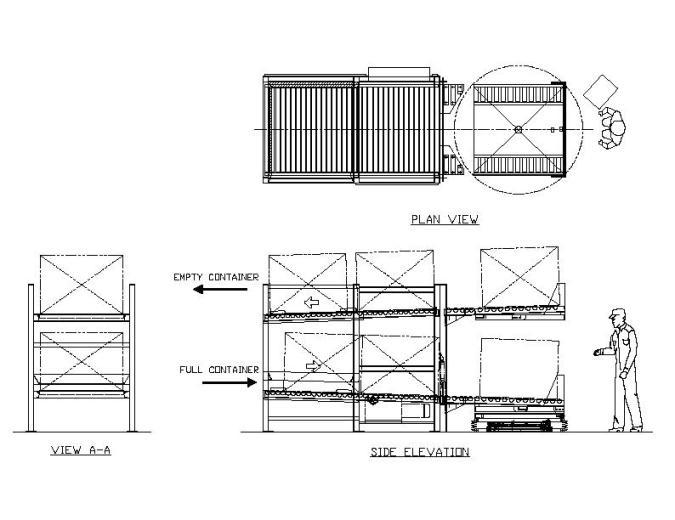

DR Storage Systems is a supplier of custom fabricated pneumatic drive turntables and carousels for WIP containers.

Pneumatic drive turntables and carousels bring a range of benefits to the management of Work-In-Progress (WIP) containers in industrial settings. These solutions are designed to enhance material handling efficiency, organization, and overall productivity. Here are the advantages of using pneumatic drive turntables and carousels for WIP containers:

- Space Optimization: Pneumatic turntables and carousels allow for efficient use of vertical space. They can be used in areas with limited floor space, providing a compact and space-saving solution while maximizing storage capacity.

- Improved Accessibility: These systems make it easier for workers to access WIP containers without the need for excessive reaching, stretching, or bending. Containers are brought to the operator at an ergonomic and convenient height, reducing strain and improving worker comfort.

- Enhanced Workflow: Pneumatic drive turntables and carousels facilitate seamless rotation and presentation of WIP containers. This rotation mechanism allows workers to quickly locate the needed items, reducing retrieval time and promoting smooth workflow.

- Reduced Downtime: With easy access to WIP containers, workers can efficiently retrieve the required components or materials. This reduces downtime and minimizes delays in the assembly or production process.

- Flexibility: Pneumatic drive turntables and carousels can be customized to accommodate containers of various sizes and weights. This adaptability makes them suitable for a wide range of industries and applications.

- Quick Turnaround: The controlled rotation of containers ensures that the necessary components are always within reach. This accelerates the assembly process and helps maintain a steady production pace.

- Organization and Inventory Control: Pneumatic systems can be equipped with sensors and control systems that allow for accurate tracking and inventory management. This helps in maintaining a clear overview of WIP containers, preventing stockouts, and optimizing inventory levels.

- Reduced Human Error: The controlled rotation and presentation of containers reduce the likelihood of human errors such as picking the wrong items or overlooking components.

- Quick Setup: Pneumatic drive turntables and carousels are relatively easy to install and integrate into existing workflows. This means minimal disruption to ongoing operations during implementation.

- Cost Savings: The improved efficiency and reduced labor time associated with these systems can lead to cost savings in the long run. Production processes become more streamlined and optimized.

- Safety: Pneumatic systems are designed with safety in mind. They reduce the risk of injuries caused by manual handling, such as lifting heavy containers or reaching for items in awkward positions.

Pneumatic drive turntables and carousels offer significant advantages for managing Work-In-Progress (WIP) containers. They enhance accessibility, workflow efficiency, and space utilization while contributing to a safer and more organized work environment.

Our project managers provide seamless integration between each manufacturer involved and the owner, while our certified installation & repair technicians bring over 25 years of experience.

Request a quote today to connect with our team.

About Us