Central Marketplace Racks

DR Storage Systems is a proud supplier of Carton Flow Rollers.

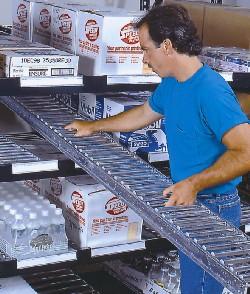

Carton flow rollers, a component of gravity flow racking systems, play a crucial role in facilitating the smooth movement of products from the back to the front of the rack under the influence of gravity. Here are some benefits of using carton flow rollers within a gravity flow racking system:

- Efficient Product Flow: Carton flow rollers provide a consistent and controlled movement of products from the rear of the rack to the picking area at the front. This ensures a continuous and efficient flow of goods, minimizing interruptions in the order picking process.

- FIFO Inventory Management: Like other gravity flow systems, carton flow rollers enable "first in, first out" (FIFO) inventory management. This is particularly important for products with expiration dates or those that need to be rotated based on manufacturing or purchase dates.

- Reduced Labor Intensity: Carton flow rollers eliminate the need for workers to manually push or slide products forward on shelves. This reduces labor intensity and physical strain, leading to improved worker comfort and productivity.

- Quick and Easy Access: Workers can easily access products at the front of the rack without having to reach deep into the shelf or move other items around. This reduces picking time and enhances order fulfillment speed.

- Minimized Product Handling: The smooth movement provided by carton flow rollers reduces the need for excessive handling of products during the picking process. This can lead to fewer instances of product damage and less wear and tear on packaging.

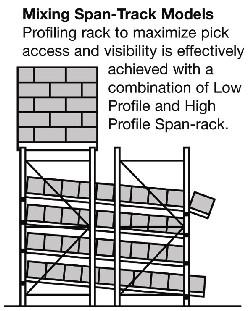

- Optimized Space Utilization: Carton flow rollers maximize the use of available vertical space within a warehouse or distribution center. This is especially valuable in facilities with limited space, as it allows for higher storage density without sacrificing accessibility.

- Versatile Product Compatibility: Carton flow rollers can accommodate a wide range of product sizes, shapes, and packaging types. This versatility makes them suitable for various industries and product lines.

- Improved Inventory Visibility: With products moving forward as they are picked, it's easier to see when inventory levels are getting low. This visibility helps with timely restocking and inventory management.

- Reduced Travel Time: Since products move closer to the picking area automatically, workers spend less time walking back and forth between shelves. This leads to more efficient use of time and increased order picking throughput.

- Customizable Configurations: Carton flow roller systems can be customized to fit the specific needs of a warehouse or distribution center. The number and spacing of rollers can be adjusted to accommodate different product dimensions and weights.

- Enhanced Order Accuracy: The organized and controlled movement of products provided by carton flow rollers can lead to improved order accuracy by minimizing the chances of picking the wrong items.

- Suitable for High-Volume Operations: Carton flow roller systems are particularly well-suited for facilities with high-volume order picking requirements. The efficient and continuous flow of products helps meet demanding picking targets.

Carton flow rollers are a fundamental component of gravity flow racking systems, offering a range of benefits that contribute to improved order picking efficiency, reduced labor intensity, and optimized space utilization within warehouses and distribution centers.

Our project managers provide seamless integration between each manufacturer involved and the owner, while our certified installation & repair technicians bring over 25 years of experience.

Request a quote today to connect with our team.

About Us